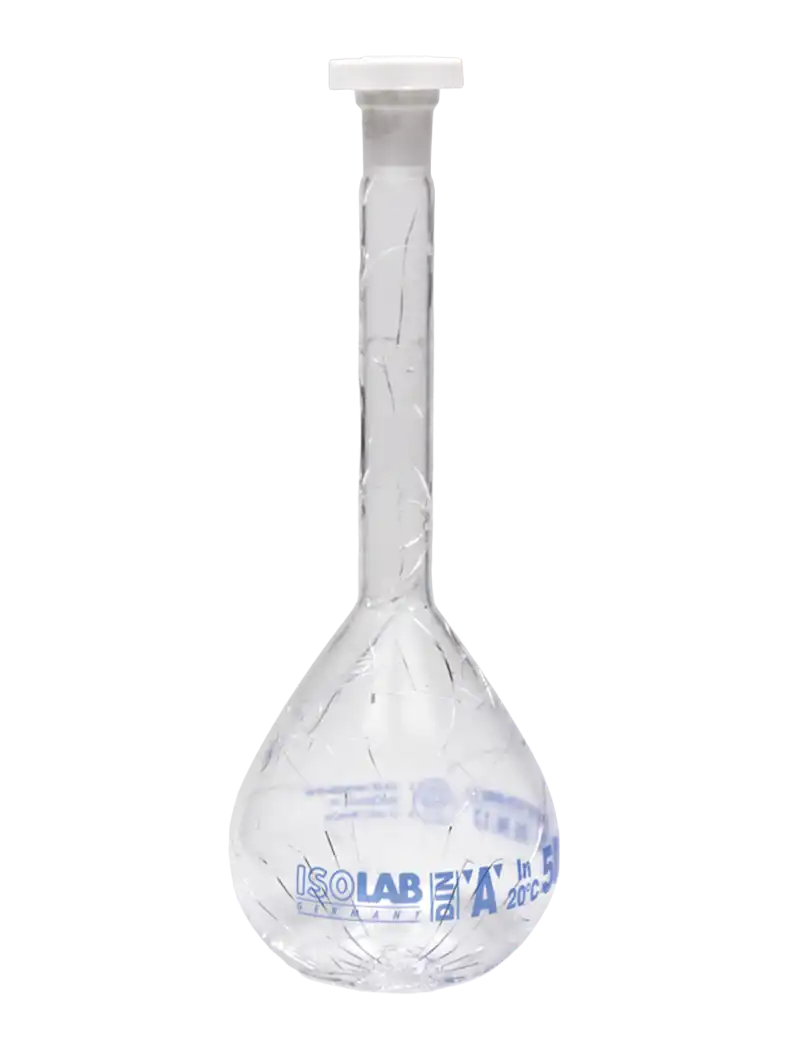

Manufactured from heat resistant borosilicate 3.3 glass according to DIN EN ISO 1042 standard. Calibrated by automatic robots according to DIN/ISO Class “A standard.

Conformity mark (“DE-M”) and batch number printed on the body surface. Batch certificate can be downloaded from website.

Individual calibration carried out by automatic robots eliminate possible deviations from nominal values.

Blue and white colored diamond grinded meniscus ring mark offers longer persistence. Inscriptions on the flask bodies are printed with long lasting enamel color.

When handling dangerous and/or valuable solutions coated volumetric flasks are highly recommended.

Bodies of these flasks are coated with a special formulated coating which reduces the impacts and also minimize the possible risks in case of breakage. Coating covers the body like a protective glove and holds the broken parts unscattered.

The coating also holds the broken glass together so that the leakage will be minimum. In most of the cases this coating keeps the solutions still inside the flask body without leakage.

The coating is highly transparent and can resist up to 135°C with maximum period of 30 minutes. They can be cleaned at maximum 95°C and can be autoclaved at 121°C.

Flasks are supplied with a leak-proof P.E stopper which ensures perfect closure.

WARNING: Coated volumetric flasks should not be exposed directly to open flame.

How to Use Volumetric Flasks:

Volumetric flasks are mainly used for preparation of highly accurate solutions.

First add the exact weight of the product inside the flask.

Fill the flask about half the volume and mix the content.

Then fill again until the level reaches a bit lower than calibration ring mark.

Adjust the temperature of flask and the content to 20°C.

Add a little more liquid so that the meniscus will be exactly at the same level of the ring mark.

Pay attention to read the meniscus at the eye level also not to wet the inner neck wall above the ring mark.